GETPOINT is a LISP command that gets the X, Y, and Z values of a point that the user picks on the drawing. We will look at the inside set first which is:

The next line is a set of nested parentheses. Again, this is just to make it easier to read. You can place blank lines in the program to separate parts that do different things. Blank lines also do not matter to the program. The indentations help to see how things are nested. Indentations do not matter to the program and just make things easier for people to read. You use this to make notes to yourself, or comments, inside the program. The next line down is “ This is a demonstration”.Īnything with a semicolon in front of it is ignored. You can ignore the set of parentheses at the end of TEST for now. So, what we have talked about so far is this: If this program were loaded into a drawing, you could type TEST at the Command Line and the program would run. If you put C: in front of the name, that name becomes a Command Line command.

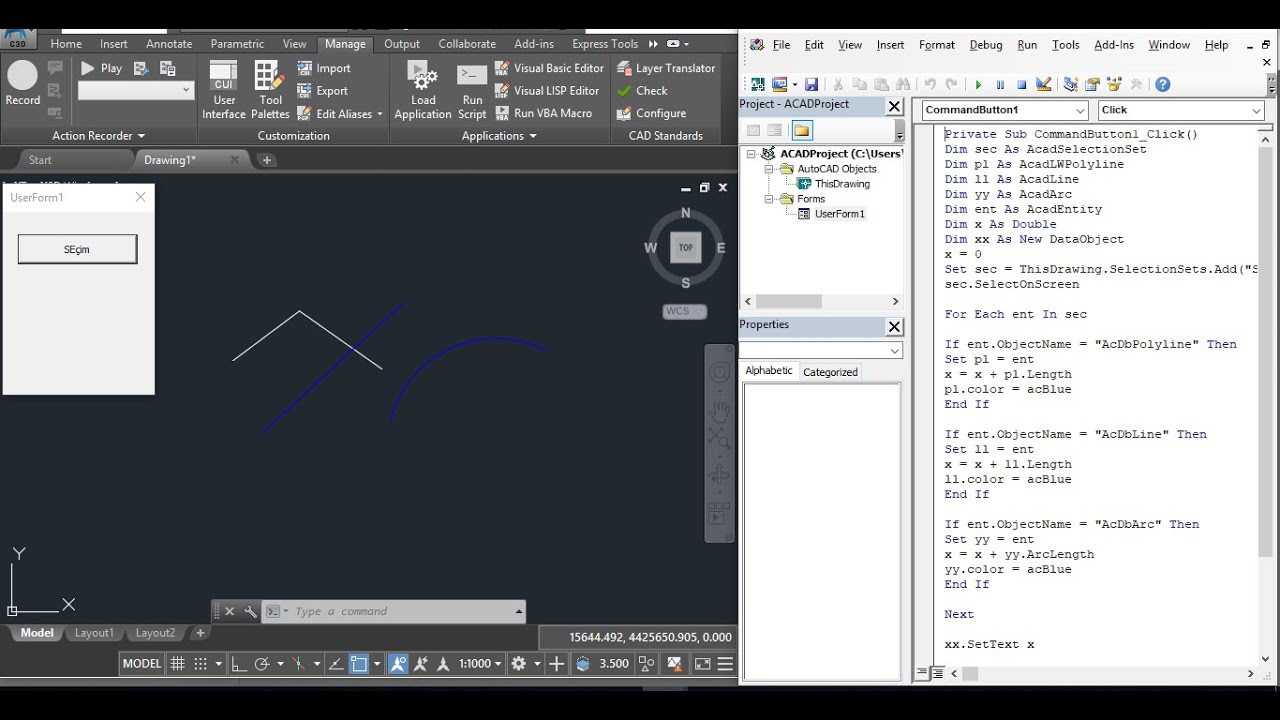

After DEFUN comes the name of the function. Every program also begins with DEFUN which stands for DEFine FUNction. Every program begins with an open parenthesis and ends with a close parenthesis. LISP programs consist of parentheses nested inside of parentheses. (COMMAND “TEXT” PT “1” “” “HELLO WORLD” “”) (SETQ PT (GETPOINT “Pick a point on the screen:”)) You can, however, get by just using a plain old text editor. It has a lot of neat features to make it easier to create and test programs, so you may want to check it out. VisualLISP is essentially a special text editor used to create and test LISP programs. Any text editor that can save files as Plain Text can be used to create LISP programs. txt file, except that the file extension of the file name has to be. LISP is built into AutoCAD there is nothing extra to buy. From here on I will refer to AutoLISP as just LISP. We are going to start out with some AutoLISP basics. If you already know AutoLISP, you may find my explanations a little simplistic, but I am trying to keep it as simple as I can for those that don’t, so please bear with me. However, I will explain those things that you need to know about AutoLISP in order to accomplish what we are trying to do.

There are plenty of good books on the market that do that.

#Autocad vba polyline bulge code

If the code is then manually edited, the simulation will not be accurate. Instead, they use the same tool path drawing that was used to generate the CNC code. Many commercial programs will simulate the operation of the machine, but do not use the CNC code to do it.

#Autocad vba polyline bulge how to

The last chapter, G-CODE TO DRAWING, will show you how to reverse the process and generate a drawing of the tool path from the CNC code. From there, you can add as many bells and whistles as you desire. This book will show you the basic principles to get you started. Perhaps you can not find a commercial program that does exactly what you want it to do, what your needs are don’t warrant the cost of a commercial program, you want more control of the CNC code, or you may just enjoy the challenge of doing it. There are many reasons why one might want to create his own programs to generate CNC code from tool paths drawn in AutoCAD. No liability is assumed for incidental or consequential damages in connection with or arising out of the use of the information or programs contained herein.ĪutoCAD and AutoLISP are registered trademarks of Autodesk, Inc. The author makes no express or implied warranty of any kind and assumes no responsibility for errors or omissions. It is assumed, however, that the reader does know AutoCAD and G-code. The programming language used is AutoLISP, but the article assumes the reader knows nothing about AutoLISP (this could also be done with VBA or VSTA).

This article presents the basics on producing G-code using nothing but AutoCAD and one of its built-in programming languages. Don Jones has spent the past 20 years using and customizing AutoCAD in the stair manufacturing industry.

0 kommentar(er)

0 kommentar(er)